1. Evaluation of mechanical properties and material design of polymers and polymeric composites

Application of polymers and polymeric composites are expanded to several mechanical structures and components since the materials have good mechanical properties with light weight. In the research, while mechanical properties of polymers and polymeric composites are evaluated, materials having excellent properties are also developed and designed.

Application of polymers and polymeric composites are expanded to several mechanical structures and components since the materials have good mechanical properties with light weight. In the research, while mechanical properties of polymers and polymeric composites are evaluated, materials having excellent properties are also developed and designed.

1) Evaluation of mechanical properties including time-temperature dependence

2) Development of material for impact energy absorption

3) Resolution of inhomogeneity and heterogeneity effects on mechanical properties

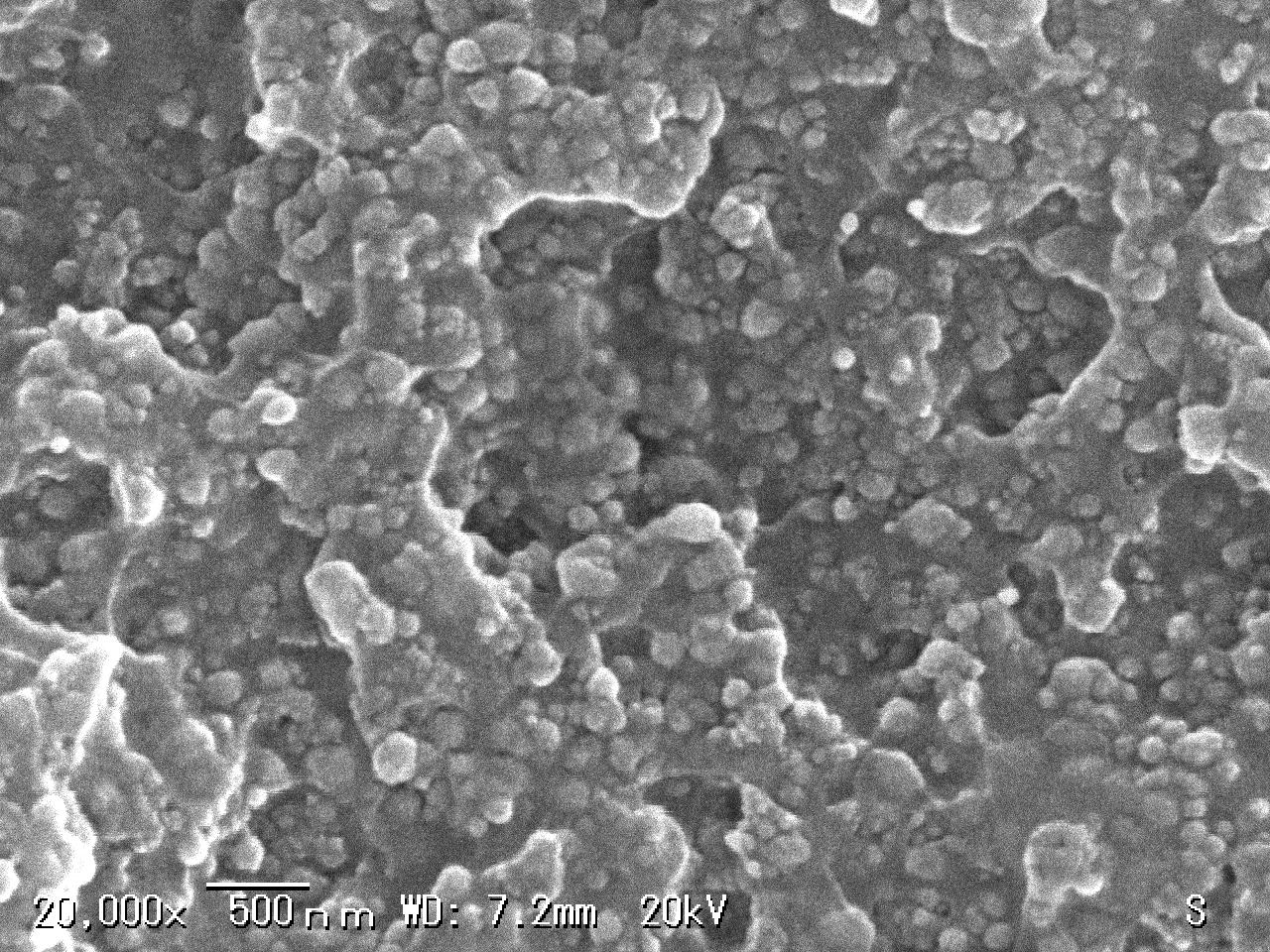

4) Material design of mechanical properties by using nano-composites

5) Development and design of functional graded polymeric foams

Keywords: polymer/resin/composite/mechanical property/material design/time dependence/temperature dependence/thermo-viscoelasticity/nano-composite/foam/impact energy

2. Development and design of mechanical systems for absorption of impact energy

When a vehicle including automobiles collides, structures of the vehicle are crushed to absorb impact energy for safety of occupants and pedestrians. In the research, mechanical components are developed to collapse efficiently for the energy absorption. New mechanical components and their control system which have high stiffness and strength of the components during normal operation and high energy absorption only during the collision are developed.

1) Development of mechanical system

2) Development of active control for impact energy absorption

3) Development of mechanical component for impact energy absorption

4) Evaluation of mechanical properties of metallic foams

Keywords: vehicle/collision/impact energy/energy absorption/collapse/smart structure/metallic foam

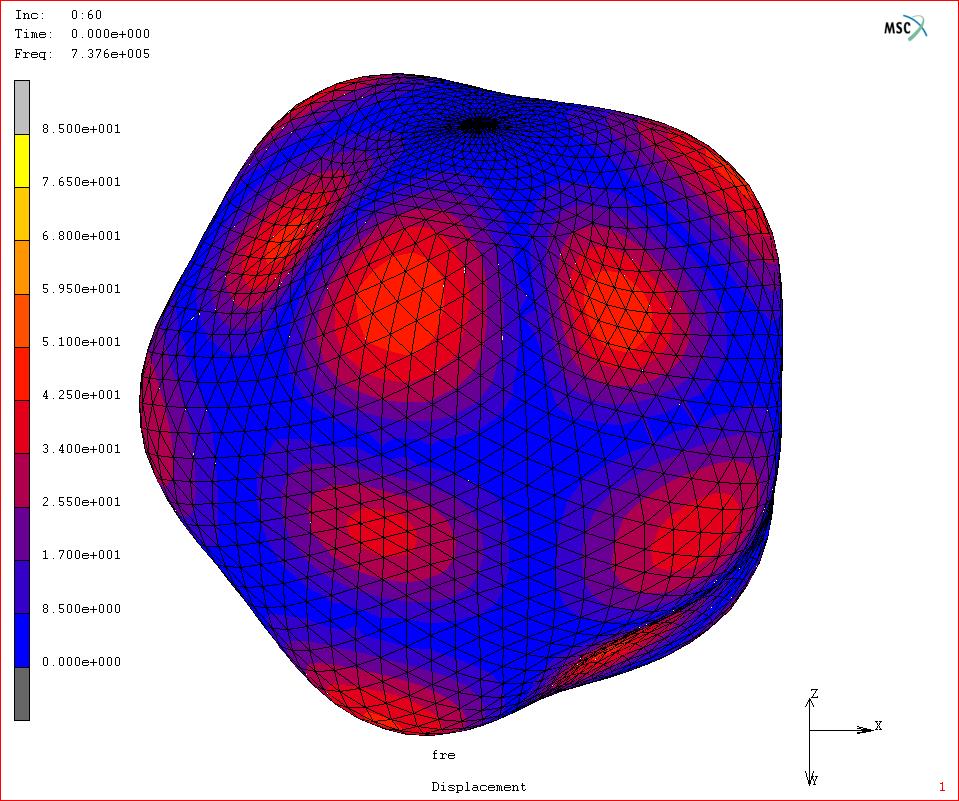

3. Nondestructive measurement of mechanical properties and evaluation of micro defects by ultrasound

Nondestructive inspection and measurement are widely applied to several materials and structures. In the research, ultrasound spectroscopy systems are developed to measure mechanical properties and evaluate micro defects as micro cracks nondestructively in production process as quality control.

Nondestructive inspection and measurement are widely applied to several materials and structures. In the research, ultrasound spectroscopy systems are developed to measure mechanical properties and evaluate micro defects as micro cracks nondestructively in production process as quality control.

1) Evaluation of elastic properties and residual stress

2) Development of nondestructive evaluation method in production process

3) Development of inspection method for micro-cracks

Keywords: nondestructive inspection/ nondestructive evaluation/ultrasound/elastic property/natural frequency/residual stress/micro defect/micro crack/production process/quality control

4. Evaluation of impact strength of solder joints and development of testing machine for impact strength

5. Study on mechanical effects on growth of trees

6. Development and design of testing machine for mechanical properties of materials and structural components